High-Q MLCCs (Multilayer Ceramic Capacitors) are specialized ceramic capacitors designed for high-frequency circuits. Their defining feature is a high Quality Factor (Q), which signifies minimal energy loss and exceptional stability. The choice of internal electrode material is critical, requiring metals with high conductivity and low losses.

Pure Silver (Ag): Offers the highest electrical conductivity among all metals, minimizing resistive losses in the electrode and achieving an extremely high Q. Such MLCCs are typically classified as Class 1 types, featuring temperature-compensating dielectric materials (e.g., NPO/COG), and deliver highly stable performance.

Silver-Palladium (Ag-Pd) Alloy: Palladium (Pd) is occasionally added to increase the electrode’s sintering temperature, ensuring better compatibility with the ceramic dielectric sintering process and improving the electrode’s microstructure. However, the addition of Pd slightly reduces conductivity. Thus, for applications demanding the highest Q, high-silver-content alloys or pure silver are preferred.

Standard MLCCs (e.g., Class 2 types like X7R and X5R) use nickel (Ni) or copper (Cu) as internal electrodes due to their lower cost and suitability for high-capacitance requirements. However, these materials exhibit lower conductivity than silver, and their dielectric materials inherently have higher losses, resulting in a significantly lower Q compared to High-Q MLCCs.

The properties of High-Q MLCCs make them ideal for radio frequency (RF) and microwave circuits where frequency stability, signal accuracy, and low loss are critical.

Key application areas include:

Base stations (4G/5G): Used in RF power amplifiers (PAs), filters, resonators, impedance matching networks, and low-noise amplifiers (LNAs).Satellite communication

systems: Employed in uplink/downlink circuits and ground stations for tuning and filtering high-frequency signals.

Microwave radio: Point-to-point wireless transmission equipment.

High-precision instruments such as network analyzers, spectrum analyzers, and signal generators. These devices require internal reference and filtering circuits with exceptional accuracy and stability, where High-Q MLCCs play a vital role.

Advanced Driver Assistance Systems (ADAS): Used in RF front-end modules of automotive radars (e.g., 77 GHz millimeter-wave radars).Vehicle-to-Everything (V2X)

communication: Applied in RF circuits for vehicle-to-external communication.

Radar systems, electronic warfare (EW) equipment, and missile guidance systems, which demand components capable of maintaining high performance and reliability under extreme conditions.

Used in high-frequency circuits for high-speed data exchange and optical communication modules.

In summary, High-Q MLCCs are essential in any application involving high-frequency, high-speed signals where signal integrity is paramount.

The market for High-Q MLCCs is dominated by established Japanese and American electronic component giants, who have decades of expertise in high-performance ceramic materials and processes.

Murata: The world’s largest MLCC supplier, offering an extensive range of High-Q MLCCs, represented by series such as GQM and GRM (COG-type), widely used in various high-frequency applications.

TDK: Another Japanese leader, known for its high-performance and reliable C-series MLCCs (e.g., C0G/NPO types), with a strong presence in automotive and communication markets.

AVX (acquired by Kyocera): Provides outstanding High-Q MLCCs, such as its 100 series NPO ceramic capacitors, designed for microwave and high-frequency applications.

Johanson Technology: A U.S.-based company specializing in capacitors and inductors for high-frequency, RF, and microwave applications. Though smaller in scale than Japanese giants, it is a recognized expert in High-Q and high self-resonant frequency (SRF) MLCCs, highly favored by RF engineers.

ATC (American Technical Ceramics, part of AVX): A leader in ultra-high-performance microwave ceramic components. Its products represent the industry’s highest standards, primarily used in the most demanding defense, aerospace, and microwave communication applications. They are exceptionally priced but offer unparalleled performance.

For most commercial and industrial applications, Murata, TDK, and Taiyo Yuden are the primary choices.

For specialized and high-end RF/microwave designs, Johanson Technology and ATC are often preferred.

AVX and KEMET provide broad and reliable product options.

High-Q MLCCs represent a critical advancement in capacitor technology, enabling enhanced performance in high-frequency and precision applications through the use of superior materials such as silver and silver-palladium alloys. Their deployment spans cutting-edge industries including telecommunications, automotive, medical, and aerospace, where signal integrity and stability are non-negotiable.

The market is characterized by a clear hierarchy of manufacturers, with Japanese firms leading in volume and breadth, while specialized American companies cater to niche high-performance segments. The choice of supplier often depends on the specific application requirements, balancing factors such as cost, performance, and reliability.

As the demand for higher frequency and faster data transmission continues to grow, the role of High-Q MLCCs is expected to become even more prominent, driving further innovation in materials and manufacturing processes.

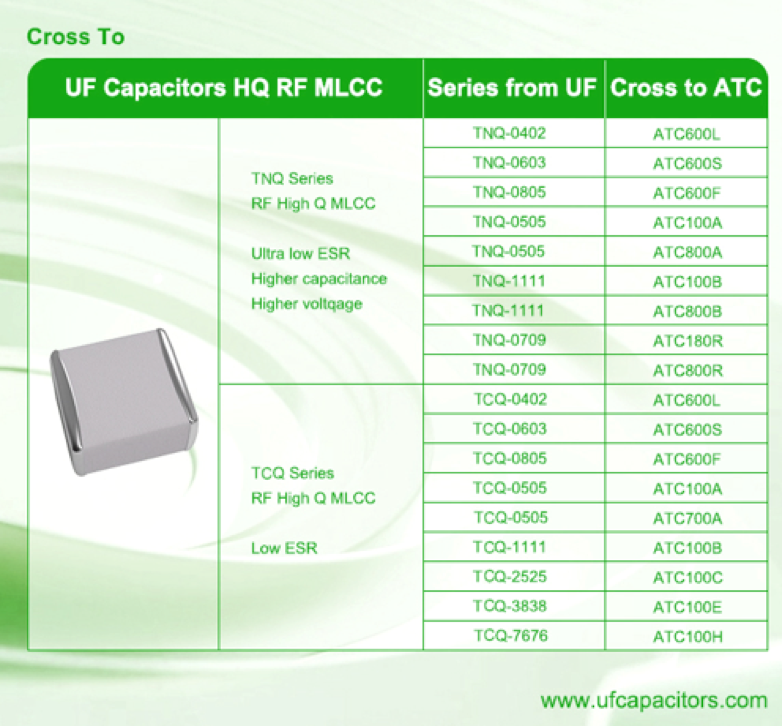

For customers seeking alternatives to ATC's ultra-high-Q, microwave-grade MLCCs, Company A offers a reliable and cost-effective solution. Specializing in high-performance ceramic components, Company A's product series excel in linearity, low loss, and temperature stability, making them well-suited for critical RF matching, filtering, and resonant circuits. While their absolute peak performance may slightly trail ATC's top-tier products, UF Capacitors provides shorter lead times and more competitive pricing while delivering sufficient performance for most commercial, industrial, and high-end RF applications—including 5G infrastructure, test equipment, and automotive radar. For designs that prioritize supply chain flexibility and cost efficiency without compromising core performance, Company A is a strong alternative manufacturer.