In the rapidly evolving electronics industry, high-voltage ceramic capacitors have emerged as essential components for modern power electronics. With the increasing demand for high-efficiency, compact, and reliable electronic systems, these capacitors are widely used in applications ranging from industrial automation to renewable energy and high-precision equipment.

As power electronics systems become more complex, ensuring voltage stability, low loss, and high-frequency performance is critical for operational safety and system longevity. Recent industry reports indicate growing adoption of high-voltage ceramic capacitors in emerging markets such as electric vehicles, energy storage systems, and next-generation power grids. These applications demand components that can withstand high stress, temperature variations, and continuous operation without compromising performance.

High-voltage ceramic capacitors are widely used in industries where voltage stability, power quality, and high-frequency performance are critical. Key applications include:

-Power Electronics: Used in DC-link circuits, inverters, and high-voltage switching modules, ensuring stable and efficient power delivery.

-Renewable Energy Systems: Support photovoltaic inverters and wind turbines by filtering high-frequency noise and stabilizing voltage under varying loads.

-Industrial Automation & Transportation: Applied in electric drives, rail systems, and industrial high-voltage modules to ensure reliable and long-term operation.

-High-Precision Equipment: Utilized in laser systems, X-ray machines, and HV test equipment where precise voltage control and low-loss performance are essential.

-Emerging Electronics Markets: Electric vehicles, grid-scale energy storage, and smart power distribution systems increasingly depend on high-voltage ceramic capacitors to enhance efficiency, ensure safety, and enable compact designs.

The high-voltage ceramic capacitor market continues to evolve with technological advances and new industry requirements. Analysts predict steady growth driven by trends in renewable energy, EV adoption, and industrial automation. Key developments include:

⚪High-Density & Compact Design: Optimizing internal structures for smaller form factors without compromising voltage tolerance.

⚪Enhanced Reliability: Advanced ceramic materials and manufacturing techniques to improve lifespan, insulation, and resistance to partial discharge.

⚪Sustainability: Focus on environmentally friendly materials and production processes to reduce ecological impact.

These trends show that high-voltage ceramic capacitors are not just components—they are key enablers of modern, intelligent, and sustainable electronic systems.

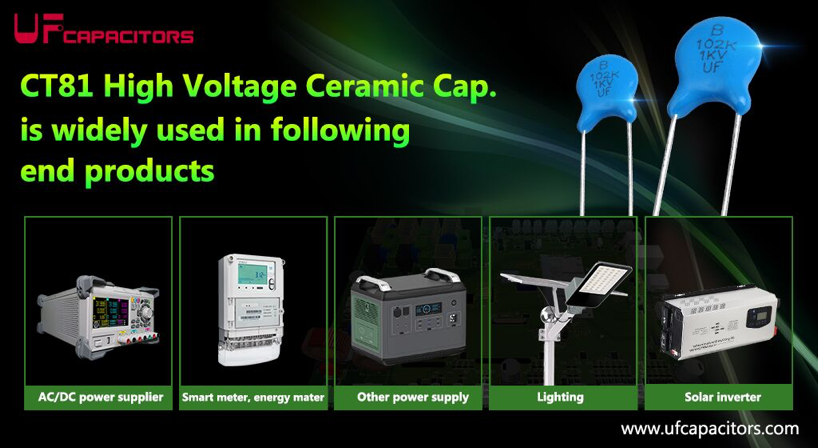

Building on these industry trends, UF Capacitors offers the CT81 Series High Voltage Ceramic Capacitors, designed to meet the stringent demands of modern power electronics. With voltage ratings ranging from 500V to 6.3 kV, the CT81 series provides excellent dielectric strength, low dissipation factor, and stable performance under continuous high-voltage stress.

Key Features:

· High insulation resistance and low dielectric loss

· Use for coupling, and by-pass circuit.

· Stable and high reliability products

Typical Applications:

· AC/DC power supplier

· Smart meter, energy mater

· Other power supply

· Lighting

· Solar inverter

As a trusted China-based capacitor manufacturer, UF Capacitors offers CT81 series capacitors as PIN-to-PIN replacements for leading global brands such as Vishay, Murata, and TDK, with competitive pricing, fast delivery (4–6 weeks), and consistent quality guaranteed by our ISO-certified production and testing facilities.

Learn more about our high-voltage CT81 Series and other capacitor solutions at www.ufcapacitors.com

Cross to:

|

Photo |

UF Capacitors' |

Vishay |

TDK/Epcos |

Murata |

Kemet |

|

|

S Series |

CK45 Series |

DEB DHR Series |

KHB Series |