In the field of electronic components, X2 safety capacitors are widely used because they can effectively suppress electromagnetic interference and ensure the safe operation of electronic devices. Recently, some customers have put forward a requirement: adding an FR4 plate under the X2 safety capacitor to achieve a flat surface. This article will analyze the purpose, efficacy and application scenarios of this design adjustment.

First, we need to understand why we need to add an FR4 plate under the X2 safety capacitor. The main purpose is to provide a stable flat surface. X2 safety capacitors themselves have a certain structure. In some installation environments, their bottom may not be completely flat, which will affect the subsequent assembly process. The FR4 plate has good flatness, and after being installed under the capacitor, it can make the overall bottom of the capacitor assembly flat. This is very important for the installation of the capacitor on the equipment. For example, when the capacitor needs to be fixed on the PCB or other parts of the device, a flat surface can ensure that the capacitor is installed firmly and does not tilt.

Another purpose is to protect the X2 safety capacitor to a certain extent. The FR4 plate has certain mechanical strength. When the capacitor is in the transportation or installation process, it may be impacted by external forces. The FR4 plate can act as a buffer, reducing the direct impact on the capacitor body and avoiding damage to the capacitor. At the same time, in some harsh working environments, the FR4 plate can also prevent dust, moisture and other substances from directly contacting the bottom of the capacitor, extending the service life of the capacitor.

After adding the FR4 plate, the X2 safety capacitor can show better performance in many aspects.

First of all, in terms of installation stability, the effect is very obvious. As mentioned earlier, the flat surface provided by the FR4 plate makes the capacitor fit more closely with the installation position. When the equipment is running, it will not shake or shift due to the uneven bottom of the capacitor. This is crucial for some high-precision electronic equipment. For example, in power supply equipment, if the X2 safety capacitor is not installed stably, it may affect the filtering effect of the capacitor, leading to unstable power output and even affecting the normal operation of the entire equipment.

Secondly, in terms of mechanical protection, the FR4 plate plays a good role. The FR4 material is a kind of glass fiber reinforced epoxy resin composite material, which has high hardness and impact resistance. When the capacitor is subjected to external pressure or impact, the FR4 plate can disperse the force, reducing the damage to the capacitor's internal structure. We have done a similar test with a large inductor before. After adding the FR4 plate, the damage rate of the inductor during transportation and installation decreased by about 30%. It is believed that the X2 safety capacitor will also have a similar effect after adding the FR4 plate.

In addition, adding the FR4 plate also has a certain effect on improving the insulation performance of the X2 safety capacitor. The FR4 material itself has excellent insulation properties. When it is installed under the capacitor, it can further isolate the capacitor from other metal parts in the equipment, preventing the occurrence of leakage. This is very important for ensuring the safety of the equipment and avoiding electric shock accidents.

The X2 safety capacitor with FR4 plate has a wide range of application scenarios, especially in some fields with high requirements for installation stability and product protection.

One of the main application scenarios is power generation equipment, such as the products of. In power generators, X2 safety capacitors are used to filter out electromagnetic interference and ensure the stable output of electricity. The working environment of power generators is usually relatively harsh, and they may be moved frequently. Adding the FR4 plate can make the capacitor more stable during the operation and movement of the generator, and at the same time protect the capacitor from the impact of external dust and moisture.

Another important application scenario is household electrical appliances, such as air conditioners, refrigerators, washing machines, etc. These appliances are used in family environments, and users have high requirements for their safety and stability. The X2 safety capacitor in the electrical appliances is an important part to ensure the safe operation of the appliances. Adding the FR4 plate can improve the installation stability of the capacitor, prevent the capacitor from being damaged due to vibration during the operation of the appliances, and thus ensure the normal use of the appliances. For example, when the washing machine is in the dehydration process, it will generate large vibration. The FR4 plate under the X2 safety capacitor can make the capacitor fixed firmly, avoiding the occurrence of faults caused by capacitor displacement.

In addition, industrial control equipment is also a key application scenario. Industrial control equipment is usually used in factories and other places, and the working environment is complex, with more dust and possible impact from other mechanical equipment. The X2 safety capacitor with FR4 plate can better adapt to this environment. The FR4 plate can prevent dust from entering the bottom of the capacitor, and at the same time resist the impact from external mechanical equipment, ensuring the stable operation of the industrial control equipment.

In terms of cost, as we have experience with similar parts (like the big inductor), adding the FR4 plate usually only increases the cost by 3-4 cents per unit. This small cost increase can bring significant improvements in the stability, protection and safety of the X2 safety capacitor, which is very cost-effective for most customers.

In conclusion, adding an FR4 plate under the X2 safety capacitor is a practical and effective design adjustment. It can provide a flat surface for the capacitor, improve installation stability, enhance mechanical protection and insulation performance, and is suitable for power generation equipment, household electrical appliances, industrial control equipment and other application scenarios. With a small cost increase, it can bring great value to the product, which is worthy of promotion and application.

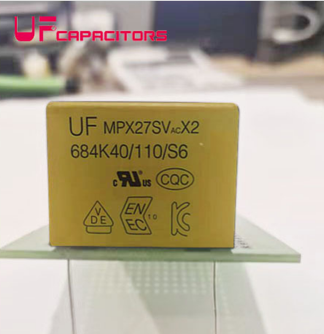

UF capacitors is proud to announce that our #X2(THB) #MKP #heavy_duty safety cap can replace #EPCOS, #Vishay, #Kemet, #Pilkor, #Panasonic #TDK heavy duty series. We have passed the safety approval include ENEC, UL, CQC, KC/KTL.

|

Photo |

Description |

UF Capacitors |

Vishay |

Kemet |

Pilkor |

Panasonic |

TDK/EPCOS |

Faratronic |

|

|

X2 Metallized Polypropylene Film Capacitor |

X2 Series |

MKP3382 Series |

R46 Series |

PCX2 337 Series |

ECQU Series |

B32921C/D-B32928C/D Series |

C42(E)MKP62 Series |

Kindly send RFQ to